Heinkel He 177

| He 177 | |

|---|---|

|

|

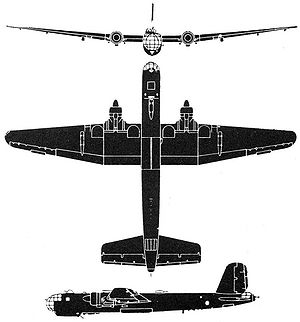

| He 177 A-02 production prototype with broad bladed propellers | |

| Role | Long range heavy bomber |

| Manufacturer | Heinkel Flugzeugwerke |

| Designed by | Siegfried Gunter |

| First flight | November 1939 |

| Introduced | 1942 |

| Retired | 1945 |

| Primary user | Luftwaffe |

| Number built | 1,169[1] |

| Variants | Heinkel He 274 Heinkel He 277 |

The Heinkel He 177 Greif (Griffin) was a long-range bomber of the Luftwaffe. This troubled aircraft was the only heavy bomber built in large numbers by Germany during World War II. Luftwaffe aircrew nicknamed it the Luftwaffenfeuerzeug (Luftwaffe's lighter) or the "Flaming Coffin" due to serious engine problems on the initial versions of the aircraft.[2] When these problems were later rectified the type was successful, but could not be deployed in numbers due to Germany's deteriorating situation in the war.

Contents |

Design

In 1936 the company of Heinkel Flugzeugwerke received details of the new Bomber A specification from the Reichsluftfahrtministerium (RLM). This specification, first proposed by the RLM on June 3, 1936, called for an aircraft more advanced than the Dornier Do 19 or Junkers Ju 89 Ural bomber prototypes. The aircraft was to be capable of carrying a bombload of at least 1,000 kg (2,204 lb) over a range of 5,000 km (3,107 mi), possess a maximum speed of not less than 500 km/h (311 mph) at altitude,.[3] This was a formidable specification, calling as it did for an aircraft able to outrun any modern fighter and outperform, by a considerable margin, any bomber then in service. On June 2, 1937 Heinkel Flugzeugwerke received instructions to proceed with construction of a full scale mock-up of its Projekt 1041 Bomber A. The mock-up was completed in November 1937, and on November 5, 1937 allocated the official RLM type number "8-177", the same day that the OKL first stipulated the requirement for the new design to possess sufficient structural strength to enable it to undertake medium degree diving attacks.[4] Heinkel Flugzeugwerke's estimated performance figures for Projekt 1041 included a top speed of 550 km/h (341.7 mph) at 5,500 m (18,045 ft) and a loaded weight of 27,000 kg (59,525 lb). In order to achieve these estimates, Heinkel's chief designer, Siegfried Gunter, employed several revolutionary features.

Engines

The He 177 required at least a pair of 2,000 PS (1,973 hp, 1,471 kW) engines to meet performance requirements. However, no engine at the time developed such power. To overcome this problem without resorting to four smaller engines and their attendant drag and maneuverability penalty, Gunter decided to employ two of the complex Daimler-Benz DB 606 "power system" setups for propulsion. This "power system", which was first introduced on the record breaking Heinkel He 119, consisted of a pair of Daimler-Benz DB 601 liquid-cooled 12-cylinder inverted-vee inline engines mounted side by side in a single nacelle driving a single propeller. The two component engines in each "system" were mounted side by side in each nacelle and inclined inwards by 30° in the vertical axis of each component engine's crankcase, so that the inner cylinder banks were disposed almost vertically, a single gear casing connecting the front ends of the two crankcases, with the two crankshaft pinions driving a single airscrew shaft gear.[5] This engine configuration stemmed directly from the RLM's, and the OKL's determination that the He 177 should be capable of dive bombing. The use of only two propellers on a heavy bomber offered many advantages such as a substantial reduction in drag, reduction of dive instability, and a marked improvement in maneuverability. Indeed, the initial prototypes and pre-production models of the He 177 displayed an airspeed and maneuverability comparable to many heavy fighters of the time. Two of the DB 606s, each of which initially developed 2,600 PS (2,564 hp, 1,912 kW) for take-off, were to power the He 177.

Surface evaporation cooling

In order to refine aerodynamic cleanliness, Gunter decided to dispense with the usual system of heavy drag producing engine radiators and to instead employ an evaporative cooling system. In the evaporative cooling system the coolant water is pressurized; thus, it is possible to heat the water to a higher temperature than its boiling point, in this case about 110° C (230° F), before steam began to form in the engine. The superheated water was then ducted away and depressurized, at which point steam formed. The water was then separated from the steam and returned to the engine. At the same time residual steam was fed through pipes in the wing and cooled by the airflow. After resultant condensation had taken place, the water from the wing pipes was also returned to the engine. During flight tests, this evaporative cooling system worked relatively well on a modified Heinkel He 100 fighter. However, even before the design of the He 177 was finalized, it was clear that such a system would be incapable of dealing with the vast amount of heat generated by the DB 606 engine. As a result, the evaporative cooling system had to be abandoned in favor of conventional annular radiators fitted directly behind each propeller, which resembled but were larger than those fitted to the Junkers Ju 88 A bomber. The addition of these radiators added significantly to the He 177's weight and drag.

Defensive Armament

Gunter's original intention had been to equip the He 177 with three cockpit-controlled remote gun turrets, with two of them intended to come from the Junkers Ju 288 program,[6] and only a single manned position in the tail. Compared with the manned turret, the idea of remotely controlled, turreted defensive armament traded technical complexity for reduction of size, weight, and drag. Furthermore, it held the advantage that the gunner could be installed in a protected position where he would have the best possible view, and where he would be less likely to be blinded by the flash from his own guns. Although work on remotely controlled aircraft defensive systems had reached a relatively advanced stage in Germany in the late 1930s, progress in this field was to prove insufficient to keep pace with the He 177. As a result the He 177 had to be modified to accommodate larger and heavier manned positions, such as the rear dorsal turret usually fitted to almost all examples of the Greif, armed with a single 13 mm MG 131 machine gun, this installation requiring that the fuselage receive structural strengthing in several locations. Eventually, most of the later production aircraft did receive a single remote forward dorsal turret, the Fernbedienbare Drehlafette (abbreviated "FDL") 131Z, armed with two MG 131 machine guns, located at a point on the fuselage directly above the wing root's leading edge, with its hemispherical sighting station's dome located slightly offset to starboard, just behind the forward cabin area.

A compact tail gun position was fitted from the beginning for rearward defense, and armed with a single MG 131 machine gun, but its streamlined glazing severely restricted the gunner's comfort, so a revised tail gun position with a bulged upper glazing design, requiring a reduction of the lower end of the rudder surface for clearance, was fitted to the He 177 A-3 and later models, the initial MG 131 being often replaced with a 20 mm MG 151 cannon.

Usually, a single 7.92 mm MG 81 machine gun in a flexible mount was mounted in the upper starboard side of the cockpit nose glazing, for defense from a direct frontal fighter attack.

The undernose Bola gondola, which was the full width of the fuselage where it emerged from under the nose, and centered under the forward cabin, usually had a flexibly-mounted 20 mm MG FF cannon at the front end, and a flexibly-mounted MG 81 machine gun in the rear for the initial A-1 version. A MG 151 cannon would replace the forward MG FF cannon in later production models, with a single MG 131 replacing the MG 81 for rearwards ventral defense.

Wing

Among the He 177's noteworthy features were its Fowler-type extensible trailing edge flaps which occupied the entire wing trailing edges, including those portions covered by the ailerons. Each aileron comprised upper and lower portions, the latter arranged to slide rearwards with flap extension while the upper part retained its function of providing lateral control for takeoff and landing. The original wing design did not take into full account the stresses resulting from the operation of the fowler flaps. A Rechlin report dated October 9, 1942 stated:

The examination has shown that the strength of the He 177's wings is one-third below that estimated by Heinkel. The reason for this is the uneven rigidity of the individual members with consequent deformation under load. This condition was not recognized by Heinkel at the proper time, the failure tests having been undertaken too late in view of the size of the structure.

Tests on the fortieth production A-1 aircraft in September 1942 revealed serious outer wing panel component damage after only some twenty flights due to the aerodynamic stress from diving attack exercises, and very costly and extensive strengthening was needed to solve the problem.[7] This significantly increasing the aircraft's weight. Starting with the later versions of the He 177 A-3, the Fowler flaps along the outboard wing sections were deactivated and removed and an additionally strengthened wing design was introduced on the He 177 A-5.

Dive Bombing

Accuracy with horizontal bombing during the years of the Ural bomber program demonstrated the weaknesses in existing German bombsights. This in itself called into question the effectiveness of horizontal bombing, whether by a medium or heavy bomber force. Some in the Luftwaffe believed that dive bombing was a more effective way to destroy targets. Technical data supported the accuracy of Stuka strikes achieving greater target destruction over Dornier Do 17s or Heinkel He 111s. The experience of the Condor Legion in Spain supported the theories of dive bombing and led some to believe that pinpoint accuracy was possible, consequently diverting them away from the idea of horizontal bombing in favor of dive bombing.

During the final inspection of the Projekt 1041 mock-up on November 5, 1937, Ernst Udet stated OKL's new divebombing requirement to Ernst Heinkel, who replied that the aircraft would never be capable of it.[4] The He 177 had to be strengthened to support the stresses imposed by the pull-out from a dive. Unfortunately, the dive bombing requirement was later increased to 60° attacks rather than the medium angle dives originally called for, resulting in further structural strengthening and an alarming increase in weight. Nevertheless, the requirement to dive bomb up to 60° was never satisfactorily solved, due to the constant increases in loaded weight. Despite the specially strengthened airframe, it was still possible to overstress the airframe during a dive attack maneuver. While the German bombsights of the 1930’s were in fact quite lacking, the follow-on versions of the Lotfernrohr 7 proved to be arguably as accurate as the American Norden bombsight. With the introduction of the Lotfe 7, which offered an average error of 20 m to 30 m (65 ft to 98 ft) from a release altitude of 3,000 m to 4,000 m (9,842 ft to 13,123 ft), and Hermann Göring's rescindment of the dive attack requirement in September of 1942, the barred-gate type dive brakes were omitted from all He 177 built after the initial pre production batch.

Undercarriage

During its initial development, the anticipated weight of the He 177 had increased so alarmingly that the provision of an undercarriage of sufficient strength began to pose a major problem. Neither the engine nacelles or the wings provided much stowage space for the main undercarriage members, which needed to be of a longer-than-usual design to allow ground clearance for the large diameter four blade propellers of the aircraft's powerplants, and after several extremely complex arrangements had been considered during the aircraft's initial design stages, a rather novel, but complex, system was adopted. Instead of the originally projected single wheel leg under each engine nacelle, two massive single wheel legs were attached to the main spar at each engine nacelle, the outboard legs retracting upward and outward into shallow wing wells, the inboard legs swinging upward and inward into similar wells in the wing roots, all units being completely enclosed by flush fitting doors, and almost "meeting" under each engine nacelle when fully extended. A more conventional single-leg twin wheel arrangement for each main gear was actually used on the two examples (one during the war, one post-war) of the He 274 in France, and a few developments that only existed as drawings actually had tricycle gear setups being fitted to the paper-only He 277.[8] The two hour time that it could take to change just one damaged main gear tire, using special Heinkel-provided 12-tonne capacity main gear jackstand blocks, which were in short supply, was just one of the myriad of problems that the He 177 A's complex main gear format brought about.[9]

Prototypes

On November 9, 1939, the first prototype, the He 177 V1 was flown for the first time with Dipl. Ing. Leutnant Carl Francke, chief of the Rechlin flight test center, at the controls. The initial flight terminated abruptly after only twelve minutes as a result of overheating engines. Francke referred favorably to the general handling and landing characteristics of the prototype but complained of some vibration in the airscrew shafts, the inadequacy of the tail surfaces under certain conditions, and some flutter which accompanied any vigorous movement of the elevators.[10]. The He 177 V2 made its first flight soon afterwards. Following Francke's initial flight, the He 177 V1 received several modifications suggested by the initial trials, including a 20% increase in the tail surface area. These modifications were not applied to the He 177 V2 when another test pilot undertook the first diving trials. During the diving trials, the V2 developed severe control flutter and broke-up in the air. Following this incident, the tail surfaces of the V3, V4, and V5 prototypes were modified in a similar fashion to those of the He 177 V1. The He 177 V3 was allocated the task of power plant development. The V1 through V3 prototype airframes were all equipped with two counterclockwise rotating DB 606 A powerplants, while the V4 prototype and all later aircraft, throughout the production run of the A-series, used a DB 606 A or DB 610 A engine on the starboard wing and one clockwise rotating B-version of the same powerplant on the port wing, so that the propellers rotated "away" from each other at the tops of the propeller arcs..[11] The He 177 V4 was retained at Heinkel's test field where it undertook diving trials. While flying over the Baltic, the He 177 V4 failed to recover from a moderate dive, crashing into the sea near Ribnitz. It was later discovered that the accident had resulted from the malfunctioning of an airscrew pitch control mechanism.

The He 177 V5 incorporated a number of changes which were principally concerned with defensive armament installations. Early in 1941, during a simulated low-level attack, both DB 606 engines burst into flames, the V5 hitting the ground and exploding. The He 177 V6 was the first aircraft equipped with main production type DB 606 A/B engines instead of the pre-production units which offered a slight increase in takeoff power by 100 PS to 2700 PS (2,663 hp, 1,986 kW). The He 177 V7 featured a revised nose section which, while generally following the contours of the nose sections employed by the previous prototypes, was considerably reinforced and embodied fewer glazed panels. In September 1941, the He 177 V8, the last of the aircraft to be built as prototypes from the outset with a different, almost "bulletlike" cockpit construction from the production He 177A series aircraft, was made available for engine tests, but owing to the urgency of other development work it was returned to Heinkel after only forty days, and it was not possible to resume engine tests in the air until February 1942. The He 177 V1 to V8 and the A-0 production prototypes are notable for having a broad-bladed set of four-bladed propellers, with blade shapes and profiles similar to those used on the Junkers Ju 88 medium bomber, which were not used on the production He 177A series aircraft.

Photos of the first eight prototypes show a largely circular fuselage cross-section, especially forward of the wing root, with the A-0 series possessing flatter sides, dorsal and ventral surfaces of the main A-series production aircraft. The choice of what was called the "Cabin 3" cockpit design on September 20, 1939 for the production A-series run,[12] placed a well-framed hemispherical "fishbowl" nose onto the He 177 A-0, giving it the generic "stepless cockpit", without a separate windshield for the pilot and co-pilot, that almost all German bomber aircraft had in World War II. The He 177A's "stepless" cockpit's forward glazing had its characteristic framing of four supporting frame members running in each orthogonal direction, running as the parallels and meridians on a globe would. Two sets of four roughly square windows, themselves arranged in a square of four windows each, on each side of the upper cockpit, just behind the "fishbowl's" rear edge, provided sideways vision from the cockpit for the pilot and crew. Often, the two lower rows of the "fishbowl's" windows in the lower nose were made opaque, with the exception of the bombardier's projecting bombsight window, either by painting them over or replacement with metal panels that performed the same function.

Production

Eight prototypes were completed, followed by 35 pre-production He 177 A-0s (built by Arado and Heinkel) and 130 Arado-built He 177 A-1s. The early aircraft in this batch were used for further trials, and after a brief and unhappy operational debut the remainder were also withdrawn from service. From late 1942 they were replaced by 170 He 177 A-3s and 826 A-5s, which had longer rear fuselages and slightly lengthened engine nacelles.[13]

Engine difficulties

The tendency of the DB 606 engine to ignite became increasingly serious as the test programme progressed and many of the He 177 A-0s were destroyed in accidents or engine related causes. The DB 606 engine had first been introduced on the Heinkel He 119 and later used on other aircraft such as the Messerschmitt Me 261 where they functioned as intended, but the extremely tight cowlings on the He 177 led to considerable problems, the most common being in-flight engine fires and engine overheating. There were several reasons for the flammability of the DB 606 engine, one of which was the common "central" exhaust manifold, serving a total of twelve cylinders, on the two inner cylinder banks of the engines, which became excessively hot and caused the usual accumulation of oil and grease in the bottom of the engine cowling to catch fire. When the pilot throttled back there was a tendency for the injection pump to deliver more fuel than was required by the engine, in addition to which the injection pump connections leaked. In order to restrict the aircraft's weight, no firewall had been provided, and the DB 606 was fitted so close to the main spar that there was insufficient space for the fuel/oil pipelines and electrical leads. The engine was frequently saturated by fuel and oil from leaking connections. At high altitude, the oil tended to foam due to a badly designed oil pump,[14] and in this condition it circulated in the engines, its lubricative qualities being severely reduced. The lack of adequate lubrication resulted in the disintegration of the connecting rod bearings which burst through the engine crankcase, puncturing the oil tanks which poured their contents on to the hot exhaust pipe collector. The tightly-packed nature of the engine installations also led to very poor access to the engines as well as very poor ventilation. As a result of these factors, as well as a lack of routine maintenance in the field, the DB 606 easily caught fire in flight. The effort to create an adequately powerful engine for the He 177 by mechanically coupling pairs of lower-power engines, while theoretically sound, proved to be difficult and time consuming to perfect, leading to numerous engine complications especially on the initial production models.

Reichsmarschall Hermann Göring, angered at the apparent slowness with which the He 177 was having its powerplant problems researched and solved late in August 1942, responded thusly to one Oberst Petersen's report on the He 177's powerplant troubles, remarking on the unusual engine configuration, and the difficulty of maintenance access, of the DB 606"s:

Why has this silly engine suddenly turned up, which is so idiotically welded together? They told me then, there would be two engines connected behind each other, and suddenly there appears this misbegotten monster of welded-together engines one cannot get at!

Starting with the He 177 A-3/R2, a modified engine nacelle with a new engine, the Daimler-Benz DB 610 which consisted of a pair of Daimler-Benz DB 605's, was used to eliminate the tendency for engine fires.[15] With the introduction of the DB 610 came several improvements including the relocation of the engine oil tank, the lengthening of the engine mountings by 20 cm (8 in), the complete redesign of the exhaust system which also facilitated the installation of exhaust dampers for night missions, and the setting of a power limitation on the engines which resulted in greater reliability. These modifications were successful as far as engine fires were concerned but other minor problems with the transfer gearbox between the two engines and their shared propeller remained.

Experimental weapon loads

In addition to carrying a variety of bombs, torpedoes, and guided weapons the He 177 was tested with a number of unorthodox armaments. The first of these experimental weapon schemes known to have been tested were the twelve examples of the He 177 A-1/U2 Zerstörer variant, which was armed with a pair of limited-traverse 30 mm MK 101 cannons in the extreme front of a dramatically enlarged Bola ventral gondola, and intended for ground attack, train busting, and possibly long-range anti-ship raids.[16] Later, when assigned to flak-suppression sorties in the area of Stalingrad during the winter of 1942, Luftwaffe forward maintenance units modified a small number of He 177s, fitting a 50 mm Bordkanone BK 5 cannon to the aircraft's ventral gondola. This variant was unofficially dubbed the Stalingradtyp. Although a small number of He 177 A-3/R5 models were to be built from scratch, with the larger 75 mm Bordkanone BK 7.5 ventral cannon, structural problems caused by the weapon's recoil meant that the Stalingradtyp did not see combat use outside of the original, BK 5-armed improvised handful. Five He 177 A-5s were experimentally equipped in January 1944 with batteries of thirty-three obliquely-mounted rocket mortar tubes, likely derived from components of the Nebelwerfer infantry barrage rocket system, to create the Grosszerstörer (Big Destroyer) flying battleship, meant to break up and destroy the tight combat box defensive formations used by USAAF daylight bombers over Germany. The mission of these specialized aircraft was to stalk and destroy Allied bomber formations. The bomb bays and fuselage-housed auxiliary fuel tanks were deleted on these aircraft in order to provide space for the spin-stabilized 21 cm (8 in) rockets and their firing tubes. The tubes were inclined to fire upward at an angle of 60° to the horizontal axis of the aircraft and slightly to starboard. The tubes could be fired individually, simultaneously, or in two salvoes of fifteen and eighteen. Tests with fixed balloon targets showed the potential of this system, and limited operational trials against US Eighth Air Force bomber streams were authorized. The aircraft were operated by Erprobungskommando 25, flying out of Tarnewitz. The intended mode of operation called for the He 177s to follow the enemy bomber formations, passing below and to port of the target, maintaining a difference of altitude of 2,000 m (6,562 ft) at the time of the attack from below. A few trial daylight operations were flown but no contact was made with Allied bomber formations, and as the escort fighters were becoming ever more numerous the entire scheme was abandoned.

He 177 components in other aircraft

As part of the Junkers Ju 287 program, the fuselage of an He 177 A-5 was used as the core component. Mated to a revolutionary forward-swept wing, the tail of a Junkers Ju 388, its fixed main undercarriage from a Junkers Ju 352, and twinned nosewheels from captured B-24 Liberators, the Ju 287 V1 first took to the air from Brandis airfield on August 16, 1944.

The nosegear units of the first three prototypes of the turbojet-powered Horten Ho 229 flying wing fighter were obtained from He 177 landing gear components. The first two prototypes used complete tail gear lower units (oleo strut and wheelfork), complete with wheel, for their nosegear, while the unflown V3 used a Greif's main gear wheel and tire assembly for its nosewheel, as some 40% of the Ho 229's entire weight was meant to be placed on the nosegear and wheel.

Airworthiness and handling

The initial production version of the Greif, the He 177 A-1, demonstrated a tendency for instability in the yaw and pitch axes during August 1942, during flight tests, that would have led to poor bombing accuracy in action. Shortly after these tests, the third production A-1 example (factory serial number 15153, with Stammkennzeichen of GI + BN) had its fuselage lengthened by 160 cm (63 in) just aft of the trailing edge of the wing, and tests of the modified aircraft, from the longer distance of the "tail moment" that resulted, gave a marked degree of improvement in the yaw and pitch axis stability, enough to mandate the construction of the He 177 A-3 and all later models of the He 177 with the lengthened fuselage.[17]

British Royal Navy test pilot Eric Brown related in his book, Wings of the Luftwaffe, about the visual appearance and in-flight handling characteristics of the He 177 A-5 version, one of which he flew as a captured aircraft late in the war:

Its ground stance reminded me vividly of a Short Stirling which had sunk to its knees. In fact if there had been a choice between the Stirling and the He 177 as aesthetically the least appealling of bombers then I think the German contender would have won by a short head. A check of stability showed the aircraft to be positive about all axes, but the controls were all remarkably light for such a large aircraft. Indeed I had the feeling that the elevator was dangerously light and I was all too aware of the intelligence reports of He 177s breaking up in the air so I decided to treat this control very gently. I began a cautious exploration of the aircraft's diving characteristics since the permissible acceleration was 2.3 g with a flying weight of 27 tonnes it was vital to know the exact weight of the He 177 at all times. The aircraft had an automatic pull-out device and an acceleration warning apparatus fitted, but it really was nailbiting to have to treat a giant like this immense Heinkel bomber as if it was made of glass. The stalling characteristics with flaps and undercarriage lowered the aircraft buffeted violently at 140 km/h (87 mph) before the nose dropped at 135 km/h (84 mph). The buffet experienced was so violent that I had some concerns over structural damage. Somehow the He 177 always conveyed an impression of fragility despite its size.

The He 177A's physical dimensions and empty weight were close to that of the best known American heavy bomber of WW II, the B-17, which made Eric Brown's perceived "lightness" of the Greif's control forces potentially all the more unusual.

Further development-The Heinkel He 177B

Due to continuing problems with the DB 606's configuration, much development work was being done in order to rectify engine complications, including a complete redesign of the original He 177 intended towards the creation of a four engined version of the Greif's airframe. Ernst Udet was critical of the coupled DB 606 powerplant choice for the He 177 from before the war's start, with Göring adding his input from his own frustrations with the seemingly interminable engine problems delaying the introduction of the He 177A into service. Göring was reported as stating in August 1942:

I had told Udet from the start that I wanted this beast with four engines. This crate must have had four engines at some time! Nobody had told me anything about this hocus-pocus with welded-together engines.

The RLM's requirement for the He 177 to perform diving attacks was finally rescinded in September 1942 by Göring himself, and with that decision finally rendered, Heinkel's design work on four engined versions of the He 177A, collectively named the He 177B, were then able to progress, all to be powered with four individual Daimler-Benz DB 603 engines, with each liquid-cooled DB 603 fitted with a Heinkel He 219-style annular radiator right behind the propeller for engine cooling. This task was accomplished in a considerably later timeframe than British aircraft designer Roy Chadwick had done in similarly converting the Avro Manchester. The initial design of the Manchester, like the A-series Greif with its coupled DB 606s and 610s, had similarly depended on only two very powerful and quite troublesome 24-cylinder powerplants, the British Rolls-Royce Vulture, which by 1941 had evolved under Chadwick's work into the Rolls-Royce Merlin powered, truly four-engined Avro Lancaster.

By August 1943 much of the detail work for the He 177B series aircraft was well on its way to completion, and Erhard Milch approved the creation[18] of three He 177B prototypes, designated He 177 V101 to V103. The V101 was converted from a mid-production He 177 A-3 airframe (number 535550, with Stammkennzeichen of NN + QQ), the V102 being converted from the eighth He 177 A-0 production prototype aircraft, and the V103 being converted from an existing, early production He 177 A-5 airframe, and all three of which initially retained the 177A-style tail surfaces. Because of the 177A-style single-tailed V101 prototype having increasingly serious stability problems with higher airspeeds in its flight testing, the second prototype, the V102, was the first to be fitted with an empennage of twin tail configuration that, when tested, gave the V102 significantly better in-flight handling when compared to the original He 177A's single tail design, except during the landing approach when the Fowler flaps were extended, when flown in November 1943.[19] The only photograph that exists today of any of these He 177B prototypes is one of the V101, parked outdoors on a foggy German airfield.[20][1]

The He 177B was also intended to introduce a slightly enlarged, somewhat more aerodynamic fully-glazed nose[18] that could incorporate a remotely controlled power chin turret for forward ventral defense, mounting either a pair of MG 131 machine guns or MG 151 cannon, but the nose was only tested on the fifteenth He 177 A-0 production prototype, without the chin turret, and was never fitted on any of the He 177B prototypes, which used the standard "Cabin 3" He 177A's well-framed nose. No photographs of this new nose design are known to have survived the war and only drawings exist of it in modern archives. The remaining defensive armament generally remained similar to the He 177A, particularly the twin dorsal gun turrets for the He 177 B-5, with the aft manned dorsal turret being deleted on the planned He 177 B-7 (as on the He 177 A-7) to reduce weight, and a fully powered manned Hecklafette HL 131V tail turret, carrying a quartet of MG 131 machine guns, was intended for installation on the prototypes and would have been standardized on the production aircraft, but never went beyond the mockup and working prototype stage. The cumbersome four-strut main landing gear of the A-series was retained intact for the B-series prototypes, even though their height, meant to allow clearance for the A-series' pair of large four-blade propellers, was not changed - the outer edge of the DB 603's inner engine nacelle/wing surface juncture was located right at the "centreline" of each of the twin pairs of A-series main gear strut locations, on all four of the B-series prototypes.

The first flights of the He 177B prototypes occurred between late December 1943 and early January 1944 in the vicinity of the Vienna-Schwechat airfield, at the firm's Heinkel-Süd southern production facility, where an additional prototype, the V104, whose purpose was to be the "finalized" production prototype for the He 177B-5, and also meant to be a twin tailed prototype like the earlier V102, was being completed by order from the RLM, converted from an early production He 177 A-5.

However, from late April through July 1944, repeated Fifteenth Air Force bombing raids on German aircraft production facilities in Vienna destroyed the airworthy V103 and the incomplete V104, setting back plans of producing any series examples of the B-5 version. The latest known official accounts of the whereabouts of the two He 177B prototypes that escaped heavy bombing had the V101 still at the Heinkel-Süd plant's airfield at Schwechat near Vienna, and the V102 also there at Schwechat as late as February 1945, after damage sustained from a bad landing in April 1944 while evading one of the initial USAAF 15th Air Force raids on the area, which had kept it from being flown north to the Luftwaffe's well-known central Erprobungstelle test facility at Rechlin for safety.[21] It is possible, from some accounts, that the V101 prototype might have survived until at least February of 1945 (as the V102 had) before it was scrapped, as some photos of what is stated as the damaged V101 place it at Cheb in May 1945, and showing that the V101 had even been test-fitted with a quartet of Junkers Jumo 222 engines, if verified, would conflict with Heinkel records as to the V101 having been scrapped.

The adoption of the Emergency Fighter Program in early July of 1944 dealt the final blow to the entire He 177B development program, with the Heinkel He 162 jet fighter being the only new Heinkel aircraft design that would be allowed into production.[22]

Operational history

Beset by technical difficulties in development and service, the He 177 had a troubled life. This was in part due to the overly optimistic design requirements of long range, high speed, heavy bombload, and dive bombing. Although the He 177 entered service in 1942 it was still far from operational. In an assessment of the aircraft on April 9, 1942 the newly activated Erprobungsstaffel 177 reported that the Greif had good flying characteristics, but had unacceptable engine troubles and deficits with the airframe strength. As an emergency measure it was used to supply the encircled 6th Armee at Stalingrad where it was determined that it was totally unsuited for the transport role, carrying a little more cargo than the smaller and more reliable Heinkel He 111, and was useless for the evacuation of wounded troops. As a result the He 177s reverted to bombing and flak-suppression missions in support of the Heer in the vicinity of Stalingrad. Only thirteen missions were flown and seven of the He 177s crashed in flames without any action attributable to the enemy.

As the war progressed, He 177 operations became increasingly desultory. Fuel and personnel shortages presented insurmountable difficulties, and He 177s were sitting on airfields all over Europe awaiting the replacement of engines or engine related modifications. Serviceability also was invariably low as a result of last-minute mishaps before operations. On the night of February 13, 1944 as part of Operation Steinbock, fourteen He 177 taxied out on a bombing mission, thirteen took off, one suffering a burst tire, eight promptly returned to base with overheating or burning engines. Of the four He 177s which did reach London one was shot down by night fighters. It is not always clarified that these aircraft were brand new, delivered about a week before the operation and not properly flown-in, as the air unit had moved to a new airfield the day before and lacked sufficient maintenance personnel and material. The constant attacks of Allied bombers against the Luftwaffe's long range combat units in France made continuous operations on these airfields quite difficult. Many aircraft could not be maintained properly due to destroyed hangars or were simply unserviceable due to damages caused by Allied strafing attacks.

While Steinbock could be considered as an unsuccessful operation, the He 177 did achieve some successes. The more experienced crews typically carried two 1,800 kg (3,968 lb) and two 1,000 kg (2,204 lb) bombs. Climbing to 7,000 m (22,965 ft) while still over German territory, the He 177s approached the target in a shallow dive, each aircraft throttled back, the pilot putting his aircraft into a gliding descent to take it across the bomb release-point at about 4,500 m (14,763 ft). After releasing the bombs the pilot re-opened the throttles, but continued the descent at approximately 200 m (656 ft) per minute. The bombers typically re-entered German airspace at an altitude of 750 m (2,460 ft), and headed back to base. By such means, the He 177s were able to keep up speeds of about 600 km/h (373 mph) to 700 km/h (435 mph) during their withdrawal phase. The higher speed and constant change of altitude made the aircraft harder to intercept, increasing the survivability of the aircraft, but contrarily decreased bombing effectiveness. In fact, with an average loss rate of 60% for every type of bomber used in Operation Steinbock, the He 177s had a loss rate well below 10%, making them the most survivable bomber used in this campaign.

During operations on the Eastern Front in early 1944, often carried out in daylight at about 6,000 m (19,685 ft) or higher, losses were relatively light. The Soviet Air Force, equipped mainly for low-level interception and ground-attack roles, was able to do little to hinder the high-flying bombers. Individual pilots did make interceptions but, unaccustomed to engaging such comparatively large targets and disconcerted by the effective defensive armament, they rarely pressed home their attacks.

In common with most German bombers, the He 177 was grounded from the summer of 1944 as the Allied bombing campaign began to seriously affect German fuel production. By this time the He 177 had proved itself to be the most technically advanced bomber of the Luftwaffe. This was confirmed by postwar tests on the He 177 A-5 and the single long-range He 177 A-7, which the Royal Air Force found impressive. The He 177 can be compared with the B-29 Superfortress which also took about two years to have its problems ironed out, after which it became one of the most successful bombers of aviation history. However, due to the Emergency Fighter Program, fuel shortages, and the deteriorating war situation in Germany the He 177 was never able to achieve its full potential.

Variants

- He 177 V1 to V8

- 8 prototypes built in total. He 177 V4 and subsequent aircraft powered by DB 606 A/B engines.

- He 177 A-0

- Pre-production series, 35 built.

- He 177 A-1

- First production series, 130 built. Armed with a single MG 81 in the nose, a single MG FF cannon in the forward end of the Bola ventral gondola, a remote controlled dorsal turret with a single (later twinned) MG 131, and a single tail mounted MG 131.

-

- He 177 A-1/R1

- Equipped with a supplementary pair of aft firing MG 81 in the rear of the ventral gondola.

- He 177 A-1/R2

- Equipped with a sighting station in the rear of the ventral gondola for a remotely controlled ventral turret housing a single MG 131.

- He 177 A-1/R4

- Equipped with a supplementary aft firing MG 131 in the rear of the ventral gondola and a manned aft dorsal turret containing an MG 131.

- He 177 A-1/U2

- Zerstörer heavy fighter with a pair of 30 mm MK 101 cannon in lower nose mount, twelve conversions.

- He 177 A-2

- Proposed four-man pressurized variant with reduced defensive armament of six MG 81 and a single MG 131, never built.

- He 177 A-3

- Second production series, 170 built. Sixteenth and subsequent aircraft powered by DB 610 A/B engines.

-

- He 177 A-3/R1

- Powered by two Daimler-Benz DB 606 A/B engines, fifteen built.

- He 177 A-3/R2

- Improved electrical system. MG FF cannon replaced by an MG 151 cannon in the ventral gondola. Larger redesigned tail position, MG 131 replaced by MG 151 cannon in the tail position.

- He 177 A-3/R3

- Anti-shipping version capable of using the Henschel Hs 293.

- He 177 A-3/R4

- Ventral gondola lengthened by 1.2 m (3 ft 11 in) to provide room for the FuG 203b Kehl III missile-control equipment.

- He 177 A-3/R5

- Stalingradtyp version armed with a 75 mm Bordkanone BK 7.5 cannon based on the 7.5 cm PaK 40 installed in the ventral gondola, also used on the Junkers Ju 88 P-1 only five built.

- He 177 A-3/R7

- Torpedo bomber version abandoned in favor of the He 177 A-5, only three built.

- He 177 A-4

- Proposed high altitude pressurised version, never built under the designation, and later developed into the Heinkel He 274.

- He 177 A-5

- Main production series, 826 built. Strengthened wing, shortened undercarriage oleo legs, increase in maximum external bombload.

-

- He 177 A-5/R1

- Version optimized for Fritz X and Hs 293 guided bombs, equipped with Kehl control gear.

- He 177 A-5/R2

- Armed with a single MG 81 in the nose, a single MG 151 cannon in the forward end of the ventral gondola, a pair of MG 81 in the rear end of the ventral gondola, a pair of MG 131 in an FDL 131Z remotely controlled forward dorsal turret, a single MG 131 in a manned aft dorsal turret, and a single tail mounted MG 151 cannon.

- He 177 A-5/R4

- Simplified bomb rack installation, equipped with Kehl control gear.

- He 177 A-5/R5

- Tested with a supplementary pair of MG 131 in an FDL 131Z aft ventral remote turret aft of the rear bomb-bay, only one built.

- He 177 A-5/R6

- Replacement of the forward and central bomb-bays with enlarged, full-fuselage-depth fuel tanks.

- He 177 A-5/R7

- Pressurised cockpit study with a projected ceiling of 15,200 m (49,869 ft) and similar reduced armament to the He 177 A-2.

- He 177 A-5/R8

- Armed with FDL-series remote gun turrets. Abandoned as a result of difficulties with the turrets, only one built.

- He 177 A-5 Grosszerstörer

- Anti-bomber variant based on the He 177 A-5, armed with 33 spin-stabilised 21 cm calibre rockets obliquely mounted in fuselage, supplanting bomb bays and auxiliary fuel tanks, and most likely based on components of the 21 cm Nebelwerfer 42 barrage rocket system. Five examples delivered in January 1944 for operational trials. Abandoned due to increasing numbers of Allied escort fighters.

- He 177 A-6

- Extensively revised and pressurised proposal for a high-altitude, long-range model with reduced armament, as on the A-2 and A-4 proposed high=altitude versions. This version had a tail turret and the capability to carry Fritz X and Hs 293. Never built, as it was abandoned in favor of the "paper-only" He 277 B-6.

-

- He 177 A-6/R1

- Rear dorsal turret deleted and tail position replaced by He 177B series HL 131V "quadmount" tail turret. Replacement of the forward and central bomb bays with full-fuselage-depth fuel tanks (as on the A-5/Rüstsätz 6 modification) and the addition of external bomb rack under the new fuel tank bays, capable of carrying a single 2,500 kg (5,511 lb) bomb or Fritz X/Hs 293 in addition to the rear bomb-bay loadout. Range of 5,800 km (3,604 mi), only six test conversions built.

- He 177 A-6/R2

- Equipped with a redesigned fuselage nose of improved aerodynamic form, generally the same as intended for He 177B development version. Retained the FDL 131 remotely controlled forward dorsal turret, a single MG 131 in a rear ventral position, a pair of MG 151 cannon in a remotely controlled FDL 151Z "chin" turret (to be standardized on the B-version), and a manned HL 131V MG 131 "quadmount" tail turret. Similar bombload and range to He 177 A-6/R1, only one test conversion built.

- He 177 A-7

- High altitude bomber with an extended wing spanning 36 m (118 ft 1⅓ in) and with DB 610 A/B engines instead of the intended 3,800 PS (3,748 hp, 2,795 kW) DB 613 engines. Six examples, for wing tests, converted from He 177 A-5 airframes. One captured by American forces, scrapped postwar and believed buried under the grounds of Chicago's O'Hare International Airport.

- He 177 A-8

- First proposed He 177 design to feature four individual engines, using the A-3 or A-5 fuselage with a new wing design, and either Daimler-Benz DB 603 or Junkers Jumo 213 engines with Heinkel He 219 style annular radiators. Remained a paper project only, before re-designation as the "He 177 B-5" in August 1943.[23]

- He 177 A-10

- Proposed four engined He 177 design, similar to the He 177 A-8, but based instead on the He 177 A-7 definitive production fuselage, with manned rear dorsal gun turret omitted, and re-designated as the "He 177 B-7" in August 1943.[23]

- He 177 B

- Developed as the direct, "separate four engined" development of the "coupled engine" powered He 177A-series, four prototypes ordered (He 177 V101 to V104) with three built and flown under DB 603 power. Originally postulated in postwar aviation books to have been a "Cover designation" for the never-produced, paper-only He 277.

- He 177 H

- Initial project designation for the Heinkel He 274.

Production

Production of the He 177 until 30 November 1944:

| Version | EHF [24] | HWO [25] | ArB [26] | Total | Production period |

| Prototypes | 8 | 8 | |||

| He 177 A-0 | 15 | 15 | 5 | 35 | |

| He 177 A-1 | 88 | 42 | 130 | January 1942 - January 1943 | |

| He 177 A-3 | 217 | 398 | 615 | November 1942 - June 1944 | |

| He 177 A-5 | 71 | 278 | 349 | December 1943 - August 1944 | |

| Total | 23 | 391 | 723 | 1,137 |

Note - One A-0, one A-3, and two A-5 rebuilt as He 177B prototypes from before December 1943 to July 1944. Source: Bundesarchiv/Militärarchiv Freiburg

Operators

- Luftwaffe

- Fernkampfgeschwader 50

- Kampfgeschwader 1

- Kampfgeschwader 4

- Kampfgeschwader 10

- Kampfgeschwader 40

- Kampfgeschwader 100

- Kampfgeschwader 200

- Flugzeugführerschule (B) 15

- Flugzeugführerschule (B) 16

- Flugzeugführerschule (B) 31

- Wekusta/OBdL

- French Air Force operated at least two He 177 A-3s left behind by the Germans and rebuilt by SNCASE at Blagnac.

-

- RAE (Farnborough) tested one He 177 A-5. An aircraft with the Geschwaderkennung code of F8 + AP from 6./KG 40 was captured by the Allies on September 1944 at Toulouse-Blagnac airfield. Transferred to the UK and was repainted with British roundels and serialled TS439.[27]

Specifications (He 177 A-5/R2)

General characteristics

- Crew: 6

- Length: 22 m (72 ft 2 in)

- Wingspan: 31.44 m (103 ft 1¾ in)

- Height: 6.40 m (20 ft 11¾ in)

- Wing area: 101.99 m² (1,097.918 ft²)

- Empty weight: 16,800 kg (37,038 lb)

- Loaded weight: 27,200 kg (59,966 lb)

- Max takeoff weight: 31,000 kg (68,343 lb)

- Powerplant: 2× Daimler-Benz DB 610 24-cylinder liquid-cooled inline piston engines, 2,900 PS (2,133 kW) each

Performance

- Maximum speed: 565 km/h at 6,000 m (351 mph at 19,685 ft)

- Stall speed: 135 km/h (84 mph)

- Combat radius: 1,540 km (957 mi)

- Ferry range: 5,600 km (3,480 mi)

- Service ceiling: 9,400 m (30,840 ft)

- Rate of climb: 190 m/min (623 ft/min)

- Wing loading: 303.9 kg/m² (62.247 lb/ft²)

Armament

- 1 × 7.92 mm MG 81 machine gun in nose

- 1 × 20 mm MG 151 cannon in forward ventral gondola position

- 2 × 7.92 mm MG 81 machine guns in rear ventral gondola position

- 2 × 13 mm MG 131 machine guns in FDL 131Z remotely-operated forward dorsal turret, full 360º traverse

- 1 × 13 mm MG 131 machine gun in manned aft dorsal turret

- 1 × 20 mm MG 151 cannon in tail position

Up to 6,000 kg (13,227 lb) of disposable stores internally or 7,200 kg (15,873 lb) externally or up to 3 Fritz X or Henschel Hs 293 radio-guided munitions

- 48 × 50 kg (110 lb) bombs (2,400 kg/5,291 lb total)

- 1 × 2,500 kg (5,511 lb) bomb (2,500 kg/5,511 lb total)

- 12 × 250 kg (551 lb) bombs (3,000 kg/6,613 lb total)

- 6 × 500 kg (1,102 lb) bombs (3,000 kg/6,613 lb total)

- 2 × 1,800 kg (3,968 lb) bombs (3,600 kg/7,936 lb total)

- 2 × 1,800 kg (3,968 lb) bombs + 2 × LMA III mines (4,600 kg/10,141 lb total)

- 10 × 500 kg (1,102 lb) bombs (5,000 kg/11,023 lb total)

- 2 × 1,000 kg (2,204 lb) bombs + 2 × 1,800 kg (3,968 lb) bombs (5,600 kg/12,345 lb total)

- 6 × 1,000 kg (2,204 lb) bombs (6,000 kg/13,227 lb total)

- 2 × FX 1400 Fritz X + 1 × FX 1400 Fritz X under the wings and fuselage

- 2 × Hs 293 or 294 + 1 × Hs 293 or 294 under the wings and fuselage

- 2 × 500 kg (1,102 lb) bombs internally + 2 × Hs 293 under the wings

- 2 × LT 50 torpedoes under the wing

See also

- Bomber B

Related development

- Heinkel He 274

- Heinkel He 277

Comparable aircraft

- Avro Manchester

- B-29 Superfortress

- Dornier Do 317

Related lists

- List of military aircraft of Germany

References

Notes

- ↑ Munson 1983, p. 292.

- ↑ Price 2004, p.162.

- ↑ Griehl & Dressel 1998, pg.8

- ↑ 4.0 4.1 Griehl & Dressel 1998, pg.9

- ↑ Griehl & Dressel 1998, pgs.92-94

- ↑ Griehl & Dressel 1998, pg.33

- ↑ Griehl & Dressel 1998, p.53

- ↑ Griehl & Dressel 1998, pgs. 159 & 195

- ↑ Griehl & Dressel 1998, pg. 218

- ↑ Griehl & Dressel 1998, pg.17

- ↑ Griehl & Dressel 1998, pg.22

- ↑ Griehl & Dressel 1998, p.16

- ↑ Munson 1983, pp. 292-293.

- ↑ Price 2004, p.162

- ↑ Griehl & Dressel 1998, pg.94

- ↑ Griehl & Dressel 1998, pgs.106-111

- ↑ Griehl & Dressel 1998, p.46 & 54

- ↑ 18.0 18.1 Griehl & Dressel 1998, p.162

- ↑ Griehl & Dressel 1998, p.163

- ↑ Griehl & Dressel 1998, p.165

- ↑ Griehl & Dressel 1998, pgs.169-170

- ↑ Griehl & Dressel 1998, pgs.170-172

- ↑ 23.0 23.1 Griehl & Dressel 1998, p.160-161

- ↑ Ernst Heinkel Flugzeugwerke

- ↑ Heinkel Werke Oranienburg

- ↑ Arado Brandenburg

- ↑ Flight International May 1945

Bibliography

- Chant, Christopher. Aircraft of World war II. Grange Books, 2000. ISBN 1-84013-336-8.

- Darling, Kev. Heinkel He 177 (Warpaint Series No. 33). Milton Keynes, Buckinghamshire, UK: Hall Park Books Ltd., 2000.

- Griehl, Manfred and Dressel, Joachim. Heinkel He 177 - 277 - 274. Shrewsbury, UK: Airlife Publishing. ISBN 1-85310-364-0.

- Hirsch, R.S.; Feist, Uwe and Nowarra, Heinz J. Heinkel 177 "Greif" (Aero Series 13). Fallbrook, CA: Auro Publishers Inc., 1967. ISBN 0-8168-0548-2.

- Mondey, David. The Hamlyn Concise Guide to Axis Aircraft of World War II. London, UK: Chancellor Press, 2004. ISBN 1-85152-966-7.

- Munson, Kenneth. Bombers 1939 - 45. London, UK: Bounty Books, 2004. ISBN 0-7537-0919-8.

- Price, Alfred. "Heinkel He 177 Greif (Griffon)". Aircraft in Profile, Volume 11. Windsor, Berkshire, UK: Profile Publications Ltd., 1972. p. 265-288.

- Price, Alfred. "He 177 Greif: The Luftwaffe's Lighter". International Air Power Review, Volume 11. Norwalk, Connecticut, USA: AirTime Publishing, 2004. ISBN 1-880588-60-9.

- Smith, J.R. and Kay, E.L. German Aircraft of the Second World War. London, UK: Putnam, 1972. ISBN 85177 836 4.

External links

- He 177's FDL 131 remote dorsal turret manual-single gun version

- Description of He 177 A-3

- He 177 A-3 manual

- YouTube German wartime footage of He 177 prototypes

- YouTube German wartime footage of He 177 V6 landing

- YouTube still photo montage of He 177s in service, with some color photos

|

|||||||||||

|

||||||||||||||

|

||||||||||||||